Troubleshooting Commercial Refrigeration Repair Service: Methods for Quick and Effective Fixes

In the world of business refrigeration, the requirement for swift and accurate troubleshooting techniques is vital. When a refrigeration system breakdowns, the repercussions can be pricey and disruptive to business procedures. Recognizing the typical issues that torment business refrigeration systems and having a toolkit of diagnostic strategies at hand can make all the distinction in quickly recognizing and fixing problems. As we browse via the complexities of troubleshooting business refrigeration repair service, we will uncover the crucial strategies for fixing issues successfully, making sure that organizations can preserve optimal cooling efficiency and minimize downtime.

Usual Industrial Refrigeration Problems

Business refrigeration systems generally run into a range of functional issues that can disrupt their efficiency and efficiency. One common issue is inappropriate temperature level control, which can lead to food perishing and waste if not without delay dealt with.

Additionally, cooling agent leakages pose a significant issue as they not only affect the cooling capability of the system but additionally add to environmental injury. Discovering and fixing leaks promptly is critical to avoid further damages and guarantee conformity with guidelines. Additionally, unclean condenser coils can hinder warmth transfer, forcing the system to work more challenging and consume more power. Normal cleaning and maintenance can help avoid this issue and extend the life-span of the refrigeration system.

Diagnostic Devices and Methods

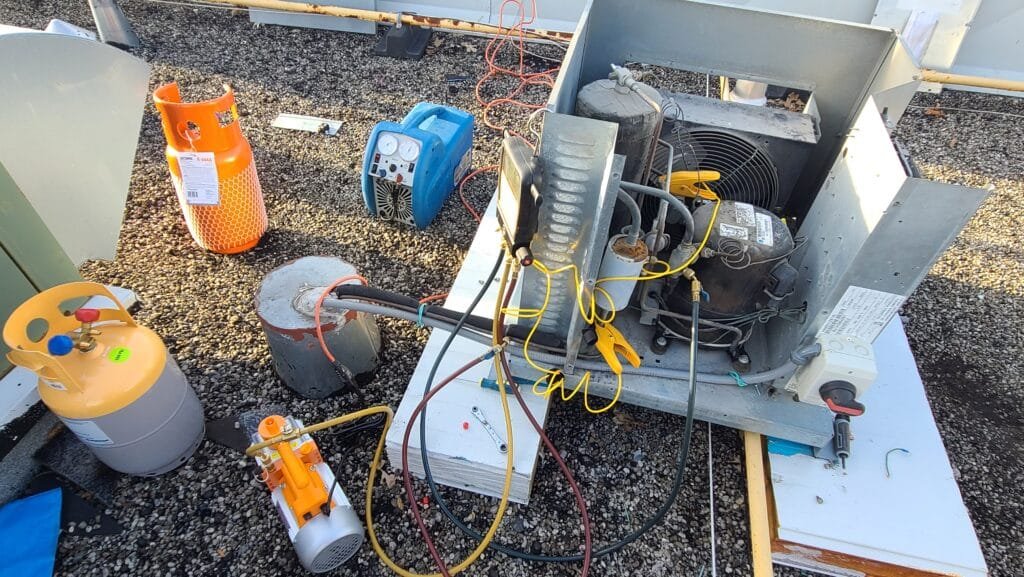

Efficient troubleshooting of commercial refrigeration systems counts greatly on utilizing specialized diagnostic tools and methods to determine and solve underlying issues efficiently - commercial refrigeration repair. Additionally, leak discovery tools like electronic leak detectors or ultraviolet dye packages are crucial for locating cooling agent leaks that can lead to system ineffectiveness.

Data loggers can be employed to check system performance over time and discover trends that might suggest repeating troubles. By combining these analysis devices and methods, technicians can effectively troubleshoot industrial refrigeration systems and offer quick and exact repair services, minimizing downtime and ensuring optimum system efficiency.

Quick Solutions for Refrigeration Troubles

When encountered with refrigeration issues, service technicians can carry out quick repairs to deal with common issues promptly and efficiently. One usual fast fix is looking for a dirty condenser coil, which can trigger the system to run inefficiently. Cleaning the condenser coil consistently can improve the system's performance and stop overheating. One more fast fix is making sure that the fridge is not overwhelmed, as overcrowding can limit air flow and result in temperature level inconsistencies. Readjusting the shelving to permit correct air blood circulation can typically settle this concern. In addition, checking the door seals for any indications of wear or damages and replacing them if required can assist preserve the integrity of the seal and stop air leaks. If the refrigeration device is not cooling correctly, examining and readjusting the thermostat setups might supply a quick remedy prior to even more comprehensive troubleshooting is required. By applying these fast solutions, technicians can address usual refrigeration troubles effectively and maintain industrial refrigeration systems running smoothly.

Preventative Upkeep Tips

Carrying out an aggressive upkeep schedule is important for guaranteeing the longevity and optimal efficiency of industrial refrigeration systems. Regular upkeep not anonymous only assists avoid pricey malfunctions however additionally makes certain that the devices runs effectively, conserving power and decreasing total operating costs. websites Here are some preventative upkeep suggestions to keep business refrigeration systems running efficiently:

Examine and Replace Filters: Unclean filters can restrict airflow, making the system work more difficult and possibly triggering damage. Examine and change filters frequently to stop issues.

Inspect Seals and Gaskets: Leaking seals and gaskets can result in temperature level changes and power wastage. Replacing and examining harmed seals can assist keep constant temperatures.

Professional Support and Provider

To preserve the optimal efficiency accomplished through routine preventative maintenance, looking for expert assistance and solutions for industrial refrigeration systems is important. Professional professionals possess the proficiency and specialized knowledge called for to identify and resolve complicated problems efficiently. When encountering difficult refrigeration issues, depending on expert assistance can save both money and time in the long run.

Professional solutions provide advantages such as accessibility to advanced devices and equipment, making certain that repairs are executed efficiently. In addition, specialists are educated to stick to sector policies and safety and security standards, reducing the threat of crashes and ensuring conformity with lawful needs.

Final Thought

To conclude, troubleshooting business refrigeration repair calls for a systematic approach to recognizing common concerns, using analysis devices and techniques, applying fast repairs, and focusing on preventative maintenance. Expert support and solutions may be necessary for even more facility problems - commercial refrigerator repair. By adhering to these approaches, businesses can ensure their refrigeration systems run successfully and efficiently, minimizing downtime and possible losses

Recognizing the typical concerns that plague commercial refrigeration systems and having a toolkit of analysis methods at your disposal can make all the difference in swiftly identifying and treating problems.Reliable troubleshooting of business refrigeration systems counts heavily on using specialized analysis tools and methods to Get the facts identify and solve underlying concerns efficiently. By combining these analysis devices and strategies, professionals can successfully repair commercial refrigeration systems and supply fast and exact repairs, minimizing downtime and ensuring optimum system efficiency.

By executing these quick repairs, specialists can deal with typical refrigeration problems effectively and keep business refrigeration systems running smoothly.

In addition, expert support can aid extend the life-span of commercial refrigeration systems by recognizing potential issues before they escalate.

Rick Moranis Then & Now!

Rick Moranis Then & Now! Judd Nelson Then & Now!

Judd Nelson Then & Now! Samantha Fox Then & Now!

Samantha Fox Then & Now! Brooke Shields Then & Now!

Brooke Shields Then & Now! Mike Smith Then & Now!

Mike Smith Then & Now!